Normally, the most expensive item on your custom wheel set quote, are the hubs. They are the heart of your wheels and come in many flavours. Ever wondered what to choose and why?

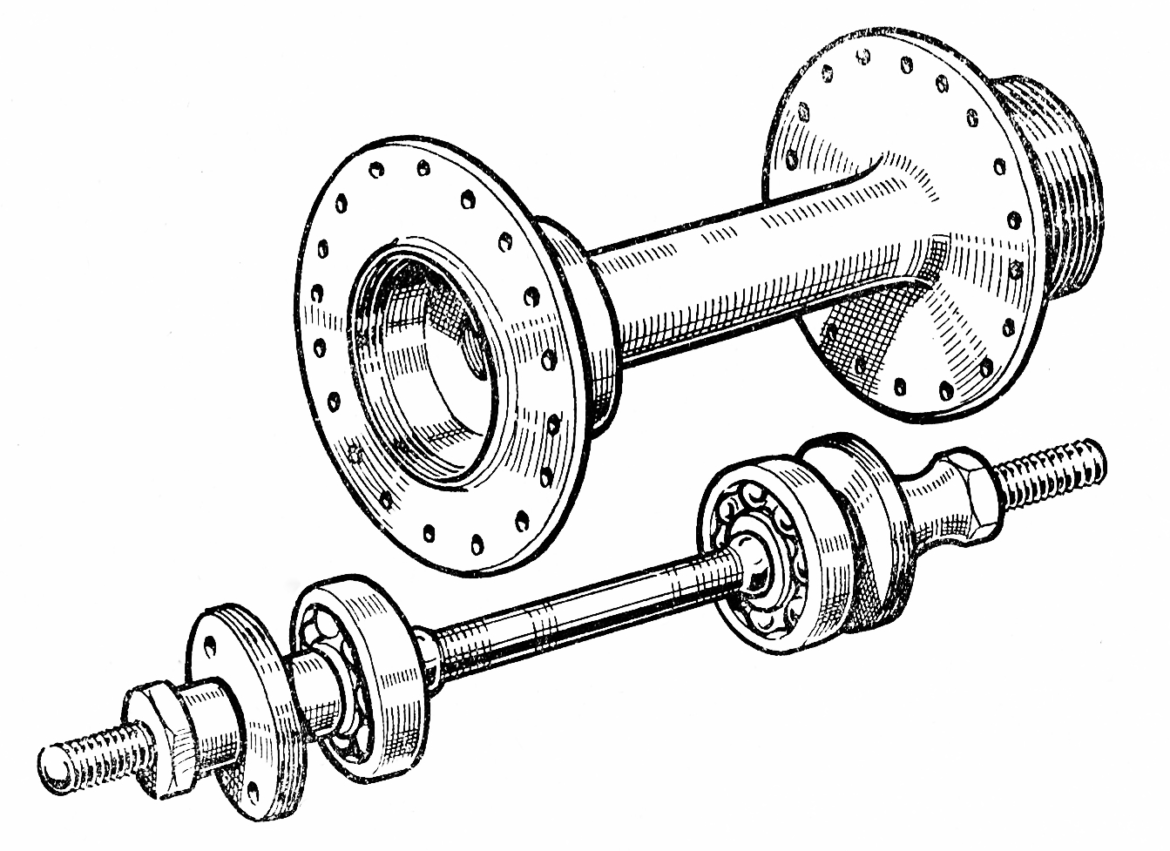

Bearings

Premium quality modern hubs almost all have sealed cartridge bearings. There are a few really compelling reasons to go for hubs like these:

-

- Performance – sealed bearing hubs have little or no adjustment necessary, simply fit and forget.

- Maintenance – when the bearings start feeling a bit rough, simply have the bearings replaced. No mess, no fuss. Old-school cup-and-cone type systems need constant (at least once a year) maintenance and can be tricky to adjust.

- Wear and tear – if your bearings die, simply replace them. Easy. If your old cup-and-cone bearings wear out, there’s a good chance the hub itself will be damaged beyond repair. If this happens you’ll have no choice but to replace the hub, and pay for an entire wheel rebuild at the same time. (ouch)

My recommendation: Use hubs with sealed cartridge bearings to extend maintenance intervals and ensure consistent, adjustment-free performance.

Compatibility

With so many axle “standards” emerging – BOOST, QR, 15mm TA, 110x20mm, 142×12, 135x10mm etc etc – you need to think hard about the wheels you buy. Will these new bling bling wheels work if you buy a new frame or fork, or new bike?

I recommend that you get hubs that are “convertible”. Many modern options come with the ability to swap axle end caps, making them compatible across many axle types, front and rear, future-proofing your wheels.

Standard or proprietary technologies

As a wheel builder, nothing is more annoying than not being able to use standard spokes and nipples when building or repairing a wheel.

- Spokes – Many brands now make hubs that use straight-pull spokes – not such a headache any more as spokes like these are becoming more freely available. Normal j-bend spokes are still the most widely used and easy to source in any given length. Bladed spokes, however, are not easy to source and come in at a premium price. (please try and use hubs that take j-bend spokes, you’ll thank me later)

- Nipples – some big brands use a proprietary nipple system, especially for UST-style rims that don’t have spoke holes in the bed of the rim. This design necessitates the use of special nipple cups which screw into the rim, not to mention special tools to build these wheels. As with spokes, avoid this headache.

I recommend you use hubs that take j-bend spokes – these are easiest and most economical to source.

There are many options available when building a set of custom wheels – prices, colours etc. Get in touch and discuss your requirements with me and make sure you get the hubs which are best for YOU.

No responses yet